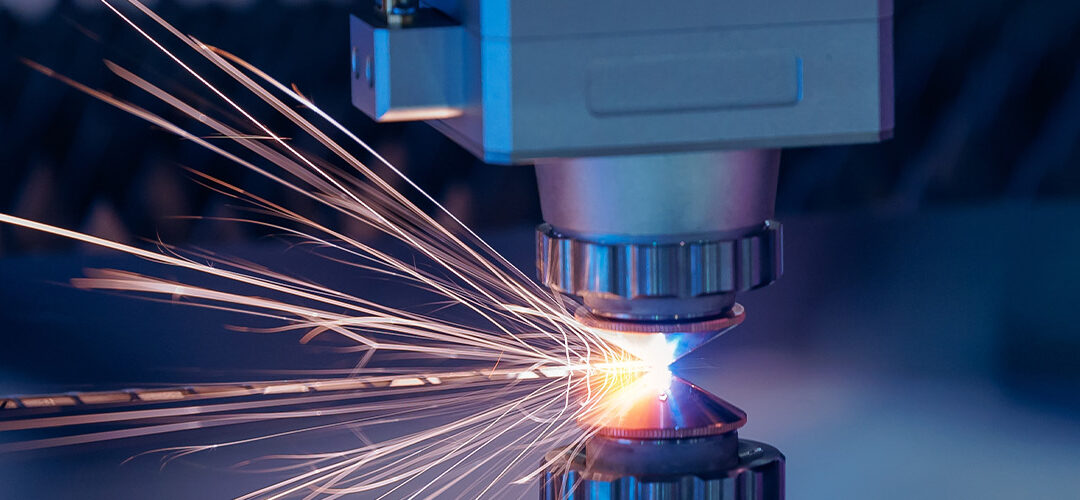

As medical devices grow more sophisticated and regulatory standards tighten, controlled manufacturing spaces have become critical. At Cadence, we’ve stepped up to this challenge by expanding our cleanroom capabilities, giving our customers exactly what they need: precision assembly, meticulous packaging, and rigorous inspection—all under carefully controlled conditions. Expanding Cleanroom Facilities to Meet Demand Recognizing the rising demand, we’ve expanded our ISO Class 7 and Class 8 cleanroom spaces across multiple Cadence facilities. These enhanced environments are specifically designed to meet the strict requirements of assembling sensitive medical devices, including implantable technologies and diagnostic tools. Delivering Fully Integrated Solutions Our cleanroom services aren’t just about assembly. We seamlessly integrate components that we manufacture in-house alongside parts supplied by our customers or third-party vendors. Our skilled teams excel in complex procedures like precision bonding, laser welding, and sterile barrier packaging, ensuring quality at every stage. Ensuring Quality and Compliance Cadence’s cleanroom operations are designed and maintained to ensure...